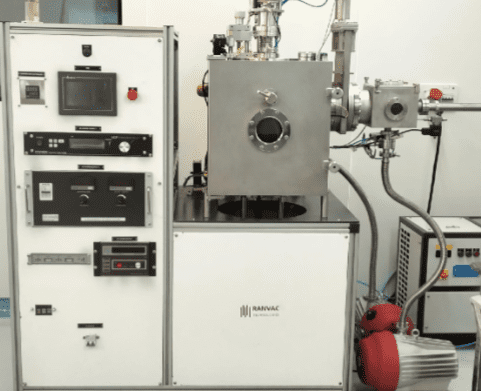

RF-DC Sputtering

RF-DC Sputtering

Key Features:

- Dual Power Modes (RF + DC): Ability to switch or combine DC and RF power sources depending on target material. DC mode is good for conductive targets (metals, etc.), RF mode allows deposition of insulating/dielectric materials without charge build-up.

- Plasma Control / Match Network: RF power systems need impedance-matching networks and blocking capacitors; they maintain and sustain plasma especially for insulating targets.

- Uniformity & Film Quality: Ability to deposit uniform films, good step coverage, density, smooth morphology. RF helps with better uniform films for dielectrics; DC often gives higher deposition rates for metals.

- Deposition Rate vs Material Trade-off: DC mode generally yields higher deposition rate for conductive materials; RF mode is slower (due to lower ion current densities etc.), but possibly better film properties (less defects, better uniformity).

- Vacuum System / Pressure Control: Needs good vacuum (low base pressure), control of inert gas (Ar) flow, possibly reactive gases. Lower pressure for better film purity. Many systems have load-lock, or dual chambers and good pumping to maintain clean environment.

- Substrate Heating / Biasing: Chambers allow substrate heating affect film crystallinity, stress, adhesion. Thermal control beneficial.

- Multi-Gun & Reactive Sputtering Options: Having multiple sputter guns so that co-sputtering or sequential deposition without breaking vacuum is possible; also reactive sputtering (with gases like O₂, N₂) to deposit oxides, nitrides etc.